Quality components, providing the best balance between price and quality.

When shopping around for a supplier for your shed you will want to ensure you are getting a competitively priced product that is suited to your site conditions. Advertised prices can be misleading as they are often based on engineering designed for the least severe conditions and will need to be upgraded to meet North Queensland’s cyclonic environment.

At Shedquarters, our designs and systems are aimed at providing the best balance between price and quality. Our shed buildings are primarily portal framed structures using cold formed steel which offers a most cost effective option for building. Comparing shed options can be difficult as there are so many elements which contribute to the strength of a shed, and different combinations of these components can provide the same outcomes. For example, larger wall girts spaced at wider intervals can provide the same structural strength as smaller wall girts spaced closer together. As you are shopping around and come across advertising slogans such as xx% stronger or xx% more steel, we encourage you to ask – stronger than what, and more steel than what? Given the number of variables that combine to determine structural strength, these claims are more often than not purely a marketing strategy with no substantiation.

Features such as .42BMT sheeting, trafficable roof, 14 gauge screws, -0.65,0.7 internal pressure co-efficients etc. are all good qualities, however they are also common to many of the shed designs available in the NQ market today, so are not always a major point of difference. We stand behind our component specifications and structural strength to favourably compare to others, assuring you of a shed to withstand cyclonic conditions, but our main competitive advantage lies in our commitment to on site compliance with design, and the service and positive overall building experience that we aim to provide.

The Details

We have tried to give an overview of our key design components below to help you make more informed choice. We are committed to maintaining the standard of our products and this is reflected in our attention to some of the seemingly smaller details.

Structural

Structural

Our shed designs are all ShedSafe Accredited, and are engineered to cyclonic conditions, with price including all design engineering and certifications required for your Development Application. We can offer a wide range of customised designs, sized to exactly meet your requirements – 1mm increments if needed. Bluescope products are well recognised for their superior performance and we use Australian Bluescope Steel and Lysaght’s

COLORBOND® or ZINCULUME® steel cladding. Shed components are consolidated, wrapped and delivered out of Lysaght Townsville.

The portal frames are all pre-drilled and bolted together using galvanised knee and apex brackets. Columns and rafters are connected using hi tensile purloin bolt assemblies (M12 for C150 and M16 for C200 and larger). Pier concrete footings are required under each column, and knee bracing can also be used to provide additional strength for higher sheds.

The portal column hold down system is usually either a galvanised base plate with screw bolts, or a galvanised stirrup bracket cast into the concrete pier. Initial quotes are usually based on whatever is more cost effective, typically screw bolts for smaller spans/lower heights or cast in stirrups for larger spans/higher heights. However if you have a definite preference, please let us know when you get your quote – we are more than happy to use either one. We also offer the options of a chemset system or a cast in J bolt.

Roller door columns and end wall columns are also connected to the slab using a galvanised base plate with a screw bolt. We do NOT use dynabolts for any structural columns.

Roller door columns and end wall columns are also connected to the slab using a galvanised base plate with a screw bolt. We do NOT use dynabolts for any structural columns.

For vertical wall cladding the roof and wall girts are Z purlins, normally Z100 with thickness varying depending on bay spans. Larger Z purlins are substituted for larger spans. Roof and wall girts are spaced depending on size and bay span and overlapped to take advantage of the increased strength of continouous span systems connected to the portal frames using purlin bolts.

For horizontal CUSTOM ORB® wall cladding, roof girts are still Z purlins or tophat, but metal stud wall frames with studs at 600mm maximum centres are constructed between the portal frames. This is a slightly more expensive option for those who want to get away from the more traditional shed appearance or if you want to match an existing structure.

Roof & Wall Cladding

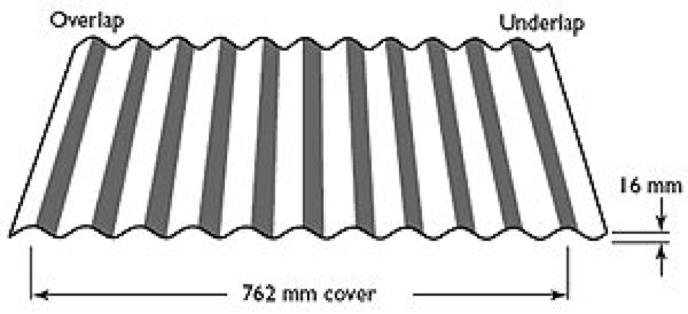

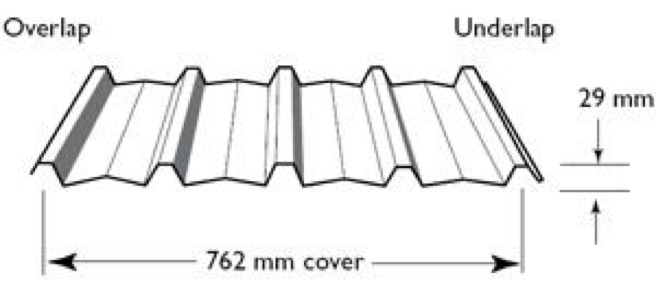

We use Bluescope Lysaght cladding and offer the two main sheeting profiles shown below. Steel is normally specified in terms of base metal thickness (BMT) which indicates the thickness of the steel before coating. Total coated thickness (TCT) indicates the measurement after coating. Roof and wall sheeting in cyclonic areas should not be less than .42 BMT. Roof and wall cladding is available in the full range of the new COLORBOND® Contemporary or Classic colour ranges. Check them out at www.lysaght.com/tools/colour-chart/colorbond-steel

Both roof and wall screws include seals for additional weatherproofing (note that some areas in Australia do not use seals on the walls screws) and are coloured to match your sheeting.

Windows, PA Doors & Flashings

Window features: Aluminium powder coated frames for a durable finish with rubber sealing to maximise weather proofing performance. Keyed locks as standard all glass used is tested to Australian Standards. Optional extras include integrated safety and insect screens with available in clear or frosted, standard toughened or laminated glass

Window features: Aluminium powder coated frames for a durable finish with rubber sealing to maximise weather proofing performance. Keyed locks as standard all glass used is tested to Australian Standards. Optional extras include integrated safety and insect screens with available in clear or frosted, standard toughened or laminated glass

Sliding windows are an economical design providing wide views with at least one sash sliding

horizontally for fully adjustable ventilation. Our windows are all provided fins on with a sill flap and are installed into a frame comprising top and bottom wall girts and folded side jambs. It is practice in some areas for the window to be held in place by simply screwing into the wall sheeting. This is NOT okay if you are building in a cyclonic region and we highly recommend that you make sure you will have an actual steel frame holding any windows in place.

Our PA doors are a fully framed style for strength and appearance, and are supplied fully assembled with the holes pre-drilled for ease of lockset assembly. We supply a high quality lockset (like a house lockset) together with proper door jambs and sturdy butt hinges as standard. The standard doors size is 820mm wide, however they are also available in 900 wide. Custom doors can also be made as an option.

Our PA doors are a fully framed style for strength and appearance, and are supplied fully assembled with the holes pre-drilled for ease of lockset assembly. We supply a high quality lockset (like a house lockset) together with proper door jambs and sturdy butt hinges as standard. The standard doors size is 820mm wide, however they are also available in 900 wide. Custom doors can also be made as an option.

Roller Doors

From 1st May 2013, changes to the Building Code of Australia mean that all roller doors require certification that they can withstand cyclonic region wind speeds. High wind kits should be included on ALL roller doors in sheds approved from 1st May, and the doors used should have formal certification of testing for the high wind rating. Please ensure that you check that there is a wind lock option included in any other quotes you receive and that a Form 15 is available from the supplier and a Form 16 from the installer, as otherwise you will run the risk of your shed failing the final building approval.

From 1st May 2013, changes to the Building Code of Australia mean that all roller doors require certification that they can withstand cyclonic region wind speeds. High wind kits should be included on ALL roller doors in sheds approved from 1st May, and the doors used should have formal certification of testing for the high wind rating. Please ensure that you check that there is a wind lock option included in any other quotes you receive and that a Form 15 is available from the supplier and a Form 16 from the installer, as otherwise you will run the risk of your shed failing the final building approval.

B&D were one of the first roller door manufacturers to design and test doors to meet the new requirements, and we use their products for both domestic and industrial roller doors. When designing your shed please be aware that you will need to allow room above the required door clearance for the roller door drum to cater for the roll when fully opened, hence your door clearance is constrained to the height of the shed less this provision. The domestic range requires a space above the door of between 400mm and 500mm (depending on the door height) and the industrial range requires up to 600mm.

Sectional doors are also available in a range of styles, however these are individually quoted and usually require additional head space to fit and operate. We are more than happy to incorporate a sectional or deco door into your project if you are keen to match an existing structure. We also have available a decorative door finish if you are chasing something different.

Sectional doors are also available in a range of styles, however these are individually quoted and usually require additional head space to fit and operate. We are more than happy to incorporate a sectional or deco door into your project if you are keen to match an existing structure. We also have available a decorative door finish if you are chasing something different.

Disclaimer

All descriptions, specifications and illustrations are intended by Shedquarters to be a general description for information and identification purposes and do not create a sale by description.